2lt_Scort

Supporter

- Total Posts : 1285

- Scores: 23

- Reward points: 5188

- Joined: 2011/08/01 11:02:49

- Location: Adelaide Australia

- Status: offline

Re: Machined parts for V6

2015/02/05 06:56:42

(permalink)

|

Jamman

Aficionado

- Total Posts : 49

- Scores: 6

- Reward points: 4943

- Joined: 2011/08/01 11:02:49

- Status: offline

Re: Machined parts for V6

2015/02/05 11:05:49

(permalink)

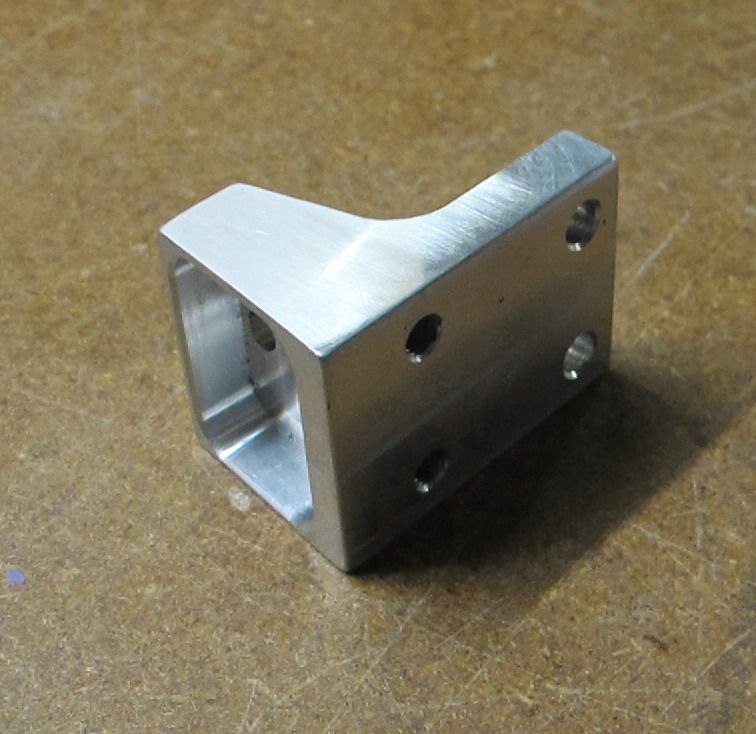

Pair of bottom radiator mounts. Machined in the dividing head from round bar.

post edited by Jamman - 2015/02/06 19:03:06

|

Jamman

Aficionado

- Total Posts : 49

- Scores: 6

- Reward points: 4943

- Joined: 2011/08/01 11:02:49

- Status: offline

Re: Machined parts for V6

2015/02/05 11:08:03

(permalink)

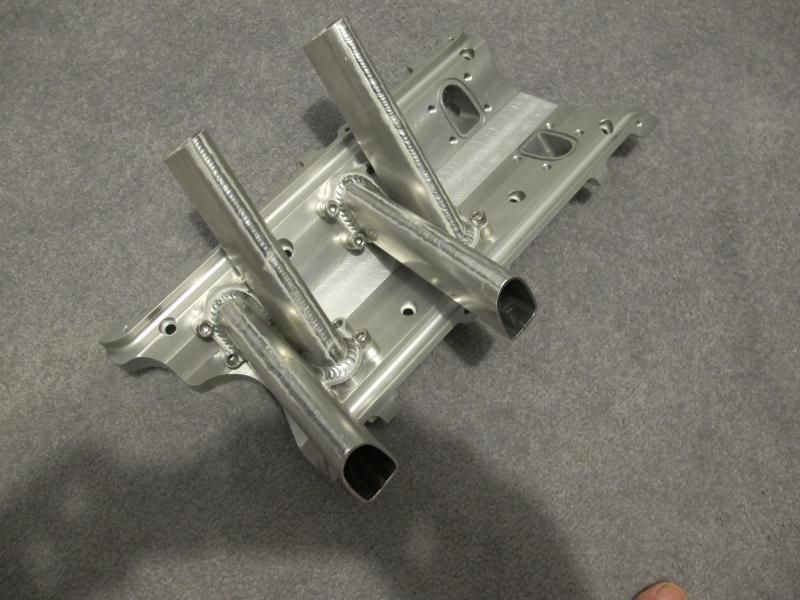

Top mounts

|

Jamman

Aficionado

- Total Posts : 49

- Scores: 6

- Reward points: 4943

- Joined: 2011/08/01 11:02:49

- Status: offline

Re: Machined parts for V6

2015/02/05 11:10:15

(permalink)

|

Jamman

Aficionado

- Total Posts : 49

- Scores: 6

- Reward points: 4943

- Joined: 2011/08/01 11:02:49

- Status: offline

Re: Machined parts for V6

2015/02/05 11:14:48

(permalink)

spud15

looks ace. Lovely work. (An aluminium block that takes later chambered heads of some type would be good)

I might have better than that!

|

spud15

Supporter

- Total Posts : 1237

- Scores: 36

- Reward points: 5597

- Joined: 2011/08/01 11:02:49

- Location: Melbourne

- Status: offline

Re: Machined parts for V6

2015/02/06 17:19:06

(permalink)

look forward to seeing it

|

Jamman

Aficionado

- Total Posts : 49

- Scores: 6

- Reward points: 4943

- Joined: 2011/08/01 11:02:49

- Status: offline

Re: Machined parts for V6

2015/02/06 19:56:21

(permalink)

|

Jamman

Aficionado

- Total Posts : 49

- Scores: 6

- Reward points: 4943

- Joined: 2011/08/01 11:02:49

- Status: offline

Re: Machined parts for V6

2015/02/06 20:05:43

(permalink)

Trial fit on dummy block.

|

Jamman

Aficionado

- Total Posts : 49

- Scores: 6

- Reward points: 4943

- Joined: 2011/08/01 11:02:49

- Status: offline

Re: Machined parts for V6

2015/02/06 20:09:22

(permalink)

Pressed 2 mm sections and then the sides machined to size and weld the halves together to form the D port shape. Next step injector bosses and plenums to join into a common throttle body. Once the distributor is removed this will make room for the throttle body.

|

hak073

Supporter

- Total Posts : 559

- Scores: 18

- Reward points: 6038

- Joined: 2011/08/01 11:02:49

- Location: Tapitallee NSW Australia

- Status: offline

Re: Machined parts for V6

2015/02/06 20:50:44

(permalink)

Wow! That is some seriously impressive machining there! Not engine parts, works of art :)

Love it. Keep the pics coming.

|

Jamman

Aficionado

- Total Posts : 49

- Scores: 6

- Reward points: 4943

- Joined: 2011/08/01 11:02:49

- Status: offline

Re: Machined parts for V6

2015/02/25 19:22:46

(permalink)

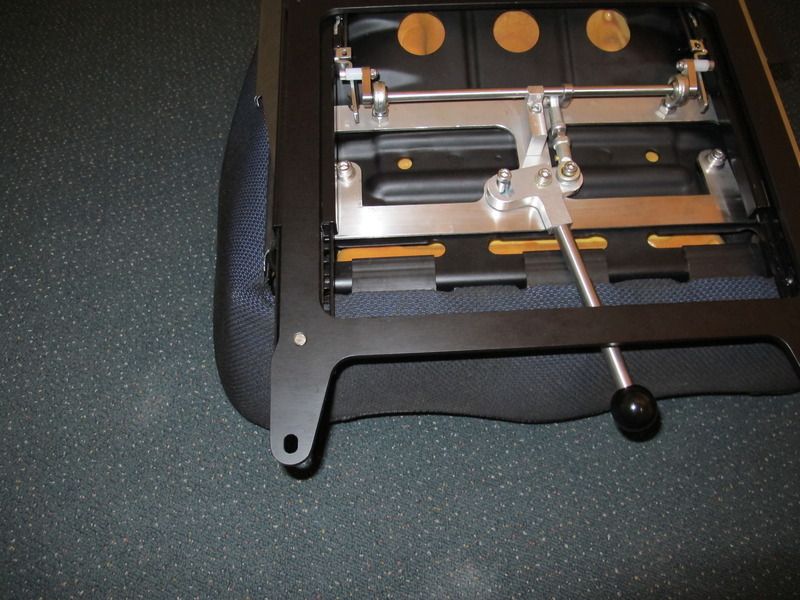

Parts back from semi gloss black anodizing. Ready for assembly and install.

|

evobda2

Scholar

- Total Posts : 412

- Scores: 20

- Reward points: 4930

- Joined: 2011/08/01 11:02:49

- Location: NSW, Australia

- Status: offline

Re: Machined parts for V6

2015/02/26 14:27:04

(permalink)

Some really great work there! Wish I had that ability to be able to do stuff like this?!!

|

gtv6capri

Deity

- Total Posts : 1461

- Scores: 53

- Reward points: 5548

- Joined: 2011/08/01 11:02:49

- Location: Melbourne Vic Australia

- Status: offline

Re: Machined parts for V6

2015/02/27 08:01:49

(permalink)

Capri The car I always promised myself

|

Jamman

Aficionado

- Total Posts : 49

- Scores: 6

- Reward points: 4943

- Joined: 2011/08/01 11:02:49

- Status: offline

Re: Machined parts for V6

2015/06/17 19:42:29

(permalink)

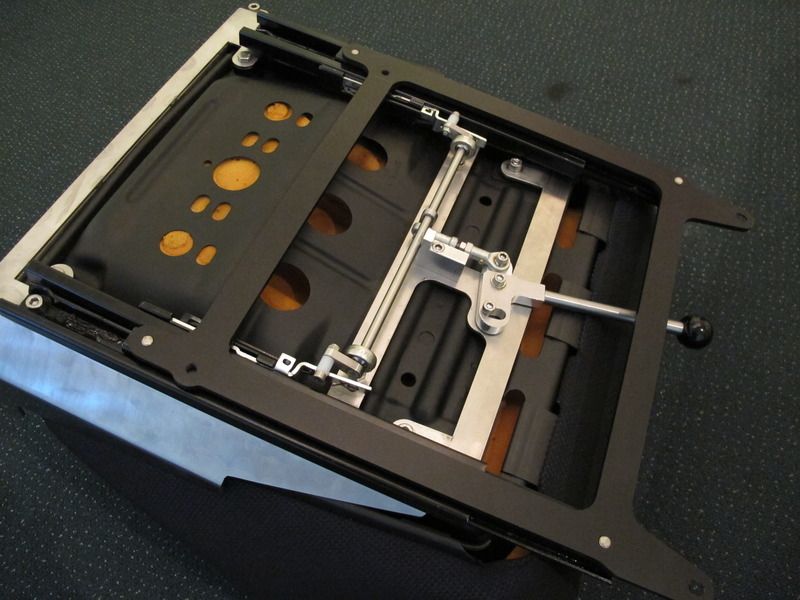

Next project complete. Subaru WRX 99 front seats installed. Massive amount of work and two prototypes before it was refined. I made up one set of seats from two sets to get good quality upholstery. One set from Brisbane and the other from Woolongong. I bought aftermarket runners and mounted inboard enough to clear the tunnel. The baseplate I machined from 6 mm aluminium, this bolts to the original spots on the floor except for the rear bolts I drilled through with studs and nuts underneath. The runners then connect to a laser cut and folded 3 mm sheet with 3/4 RHS braces in the necessary areas. I cut the original recliner mechanism off the Subaru frame and connected to my frame. The other side pivot for the back rest was designed into the sheet metal frame. The next problem was to get the adjuster mechanism to work in the narrow area. By using a lever on each side to actuate the release catches and welded to the ends of 8mm rod and pivoting on rod ends and then a horizontal lever with 6mm rod ends to connect. It worked perfectly.

post edited by Jamman - 2015/06/17 19:48:42

|