jpayne

Scholar

- Total Posts : 360

- Scores: 19

- Reward points: 2898

- Joined: 2011/08/01 11:02:49

- Location: Melbourne

- Status: offline

project 500 Mk1

well Im not sure I actually need 500 horsepowers, but I might as well build the short engine to handle it. Parts have started arriving at the London 4th floor flat, the missus is pissed that there is an engine stand in the corner of the lounge and that attached to that is a 4x4 200 block and 2wd sump and it's internals are spread through boxes around the place. Also Picked up an unmolested head with mountune race cams (bd15 and bd16 equivalent), solid lifters and lightweight vernier pulleys. and just awaiting the 4x4 inlet plenum of e-bay. I am planning to long stud the block while it is being prepped with line boring, and a basic rebuild with new accralite 8.5:1 deep valve recessed pistons and balanced internals and multi layer gasket if necessary(the block has been o-ringed so yet to determine what gasket). To this Im going for a lightweight alloy flywheel with steel insert and quartermaster or AP 7.25 inch lug drive twin plate clutch. Turbo wise probably a T4 or similar and aftermarket computer running greys or light blues or similar. In reality Im only after/will achieve 350 as the Mk1's tyres are only 7 inches wide so much more will be a waste, but I might as well build the bottom end strong enough for 500, while im here in the UK. Some photos.

|

mud

Supporter

- Total Posts : 588

- Scores: 12

- Reward points: 2753

- Joined: 2011/08/01 11:02:49

- Location: Crescent Head NSW Australia

- Status: offline

RE: project 500 Mk1

2008/01/15 12:23:31

(permalink)

[88]Nice way to decorate your flat, I hope it catches on. [:p]

Just a thought, is a lightweight flywheel a good idea for a turbo? Won't it just drop off boost more quickly?

Cam

|

jpayne

Scholar

- Total Posts : 360

- Scores: 19

- Reward points: 2898

- Joined: 2011/08/01 11:02:49

- Location: Melbourne

- Status: offline

RE: project 500 Mk1

2008/12/15 02:07:17

(permalink)

nothing like a long overdue update. I have spent this year collecting parts and serching for a decent engine builder. So far I have collected the following: AP CP5200 calipers for 310x32mm disks and alloy brackets to suit  T34 Garret 360 degree bearing  AP racing 7.25 3 plate clutch and AP ultra lightweight flywheel  6 Revolution 15x8  Also collected a reprogrammed ecu, green 803 injectors, 3 bar map sensor, more ARP fastners than I can poke a stick at, head studs, main bearing cap studs, flywheel bolts, cam caps studs, a T5 gearbox, 2wd exhaust manifold, 4wd inlet manifold, 14mm manifold spacer, freshly powdercoated black rocker cover, new alternator, startermotor, 2 round headlight grilles, a grp 4 steering coupling, double valve springs,complete set of new sensors, rebuilt distributor, 2wd wiring loom, turbo hangar and new stainless steel bolts for the block and black for alloy parts complete new cosworth gasket and seal set. Hoping to get the engine builder to accept delivery before christmas! Probably not going for 500 just a sensible 350 as I cant afford to redesign the rear end or the gearbox. Am looking for a Tilton T5 hydraulic clutch bearing assembly, and alloy brake disk hats and possibly a dry sump assembly. cheers, Justin P

|

jpayne

Scholar

- Total Posts : 360

- Scores: 19

- Reward points: 2898

- Joined: 2011/08/01 11:02:49

- Location: Melbourne

- Status: offline

RE: project 500 Mk1

2009/03/28 23:03:28

(permalink)

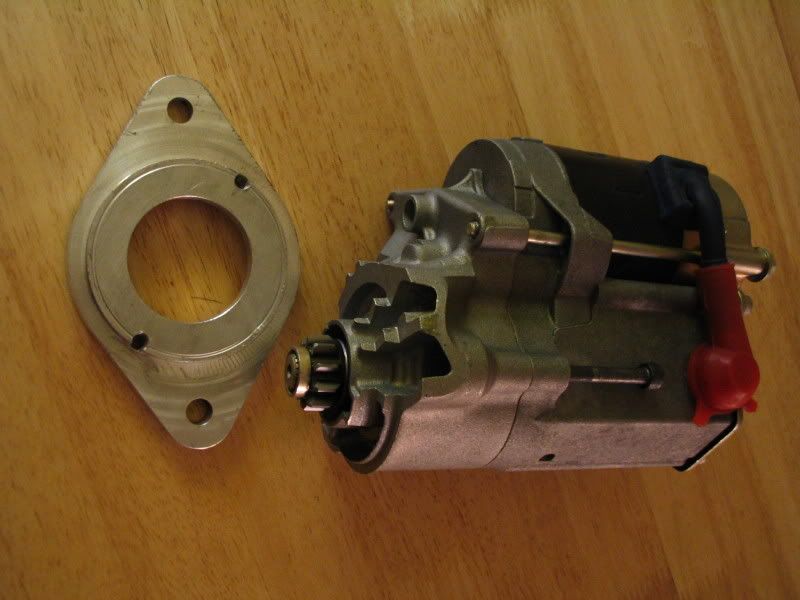

A few more parts that came cheap: starter motor, looks like an ex toyota item modified to suit  Sump baffle:  309x32mm disks and aluminium hats inside revolution 15x8's:  cheers, JP

|

jpayne

Scholar

- Total Posts : 360

- Scores: 19

- Reward points: 2898

- Joined: 2011/08/01 11:02:49

- Location: Melbourne

- Status: offline

RE: project 500 Mk1

2009/07/11 21:36:52

(permalink)

Decided the best way forward was a new cosworth head. the original one is an unknown quantity and this came up at a reasonable price. Im the third owner but its never been fitted to a car. To my surprise however it arrives having been ported to similar dimensions as described in Des Hammills book. Engine builder is to check its been done properly but my lucky day I hope as it saves me much cash not having to have it done. The crank and flywheel has been balanced, the crank having been balanced before but the combination was significantly out, engine builder suggesting it wasn't done right originally. Fortunately however it checks out straight and only required a polish of the journals. The pistons are now being pocketed and the block is having the long stud modification done...photos to follow.    JP

|

jpayne

Scholar

- Total Posts : 360

- Scores: 19

- Reward points: 2898

- Joined: 2011/08/01 11:02:49

- Location: Melbourne

- Status: offline

RE: project 500 Mk1

2009/07/11 21:37:31

(permalink)

making progress, block honed, and machined for long studs, painted and prepared.   Cheers JP

|

Mk2_2dr_2L

Supporter

- Total Posts : 528

- Scores: 2

- Reward points: 4877

- Joined: 2011/08/01 11:02:49

- Location: Toowoomba QLD Australia

- Status: offline

RE: project 500 Mk1

2009/08/11 02:47:31

(permalink)

Looking good.

Is your block lined ? What pistons did you end up using ? and if you don't mind me asking where did you buy your new head from ?

Thanks,

Damion

|

jpayne

Scholar

- Total Posts : 360

- Scores: 19

- Reward points: 2898

- Joined: 2011/08/01 11:02:49

- Location: Melbourne

- Status: offline

RE: project 500 Mk1

2009/08/11 22:37:02

(permalink)

Damion, the block has 'mig wire' wire rings inserted into the deck to help the gasket seal, its a 0.25 overbore 200 block.

Im using the standard Mahle pistons with valve cutouts machined in. My engine builder, ex mountune, believes they are more than up to the task for what I am aiming for. The head, while never being used is actually third hand, neither the original purchaser or the second could afford to use it ultimately...the recession is digging deep here. So I got a bargain, so to speak. The old head, while only having been skimmed once was showing its age and for this application was deemed a risk, it will be fine for a 250-300HP or any N/A application but not for what I want.

Whooligan, Im all for cheap, I did the sums so many times my pencil went blunt, I dont believe I could get this level of engine power for what I am spending with anything else. I bolts straight in, is tried and tested, parts are available cheap or second hand and In my case while im in the UK I have access to the right people. Plus for improved production it needs to be Ford and also it has Cosworth written across the top of the rocker cover. I believe a japaneese transplant would be more expensive for me than What I am spending on the Cossie.

Cheers

JP

|

jpayne

Scholar

- Total Posts : 360

- Scores: 19

- Reward points: 2898

- Joined: 2011/08/01 11:02:49

- Location: Melbourne

- Status: offline

RE: project 500 Mk1

2009/11/13 09:36:29

(permalink)

some more progress, dummy build to determine valve reliefs and cc'ing etc mountune long studs x6  Example of proposed valve cutouts, yet to be machined.  Bottom end all dummy built up to check clearances. rods balanced new little end bearings just to be sure! ARP main studs and ARP rod bolts

|

jpayne

Scholar

- Total Posts : 360

- Scores: 19

- Reward points: 2898

- Joined: 2011/08/01 11:02:49

- Location: Melbourne

- Status: offline

RE: project 500 Mk1

2009/11/25 22:11:56

(permalink)

Bottom end all built now. New head is having the spring seats lowered for the valve springs, should be finished in a week or two Flywheel has been skimmed and also came up great  The water pump was sat in Vinegar for two days and came up like new so a coat of paint was all that was needed   Inlet manifold has been acid dipped and should also be back soon. Cheers, JP

|

Avon

Enthusiast

- Total Posts : 255

- Scores: 1

- Reward points: 2799

- Joined: 2011/08/01 11:02:49

- Location: Perth WA Australia

- Status: offline

RE: project 500 Mk1

2009/11/26 00:46:18

(permalink)

Looking good.

That lower pulley looks big - might be a squeeze to fit behind radiator?

|

jpayne

Scholar

- Total Posts : 360

- Scores: 19

- Reward points: 2898

- Joined: 2011/08/01 11:02:49

- Location: Melbourne

- Status: offline

RE: project 500 Mk1

2009/11/12 03:31:38

(permalink)

It's done. Now I just need a car to wrap around it. Another photo of pistons. this time with pockets, clearance goo and a gasket  Another picture inside the bottom end. this time with an uprated oilpump and strainer/pickup  Front end all timed up and complete  Looks good in black, It took ages to convince Piper to let me have different coloured pulleys. I like it  Yep, Looks good in black  Really good in black!  Cheers, JP

|