One small step for man kind - one large step for the RS

The engine is in position with the modified mounts. I set it up for 60mm clearance between cross member and cut-off sump and allowing for a little sag it ended up at ummm.....60mm! Well, now allowing for 3mm plate to fill in the sump and a few mm for the sump gasket should leave me with around 10mm clearance between the bottom of the sump and the rack. I was looking more around 5 mm as I want to keep the engine low but I guess I'd rather be 5mm higher than sitting on the rack

Ironically this also allows for ample room between the Focus inlet manifold and the RHS mount which was marginal in my preferred engine position (lower).

RHS mount fitted - I need to add some gusset plates infront and behind the tube section and then finish welding. Both have limited weld incase I need to adjust the heights etc.

LHS mount - again requiring additional gusset plates.

As mentioned above - clearance between inlet and mount is now adequate.

I also need to establish a position for the factory MAF sensor - I will look into shortening the OEM intake pipe from the Ford Focus (below) to feed from the MAF to the (Focus) inlet manifold. I will likely look at a pod filter to sit on the end of the MAF sensor. I just need to figure out what and where to position the parts to determine the mounting hardware.

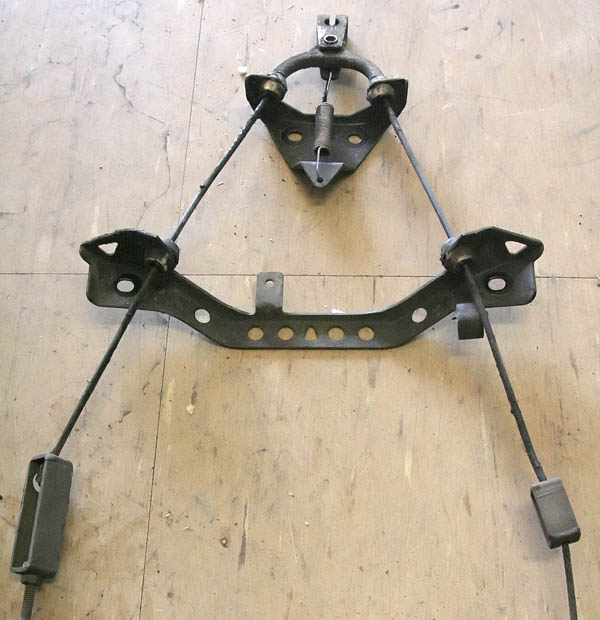

I also managed to get a hold of the Skylne hand brake set-up to position it under the shell to operate with the R31 rear disc conversion. This all just unbolted quite easily from under the donor car. All I need is to fabricate the brackets to support the leading end of the cables going to each calliper as these were welded to the R31 shell [:(!]