I had a few moments rest from the other project (http://classic-ford.org/forum/topic.asp?TOPIC_ID=21624)

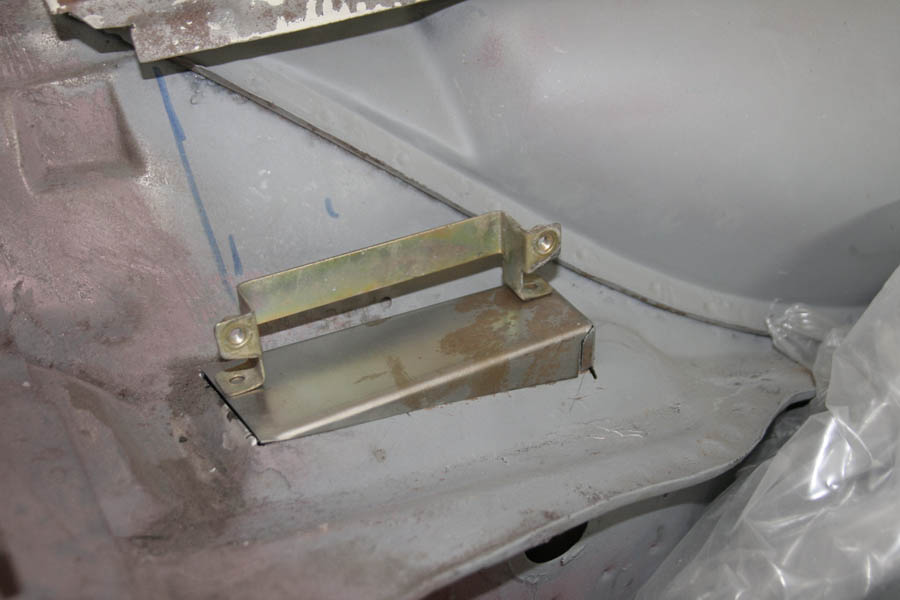

to play with this one. I have made a sheet metal version of my cardboard template to begin the reservoir mount.

Removed the section of panel to allow the reservoir hoses to access directly into the cabin and not need to go through the bulk head.

The reservoir will be fastened with it's original bracket to the added panel. I will drill holes for the hoses and barbs to penetrate into the cabin above the pedal box. It will be relatively easy to attach the hoses prior to positioning the reservoir in it's final location. I will also place a thin rubber gasket etc between the panel and reservoir to seal from the engine bay.

Hopefully I will weld it all in and buzz back the welds to make it appear to be an original panel.