Thanks Warren.

I think it handles pretty well considering how little has been done to the suspension. Unfortunately I ran out of time trying to get hold of a second rear sway bar, but I'd still be interested in trying it out. Maybe next time.

Also prior to Winton I had been doing a bit of reading on autospeed.com, as well as Zoom magazine about the benefits of pod filters. Yes, very ricey, but apparently if done right they can of great benefit and my standard airbox had restriction written all over it.

Zoom tested a bog stock MX5 with an 1800 BP engine. They simply unbolted the standard airbox, slipped on a Uni Filter sock and gained 8kw at the rear wheels!

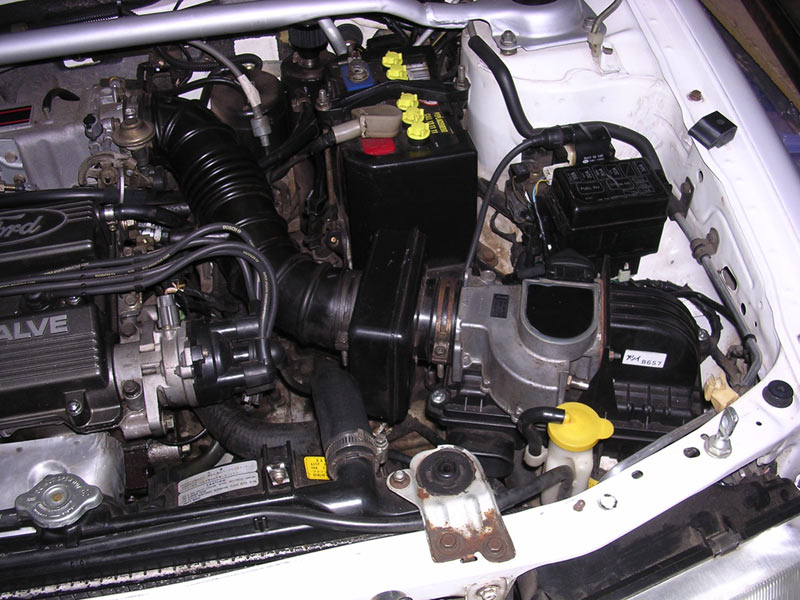

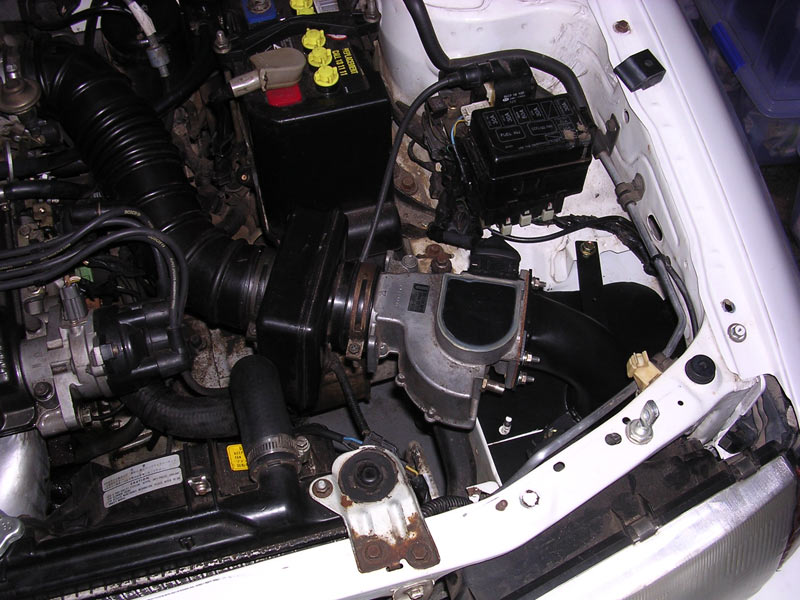

I thought I'd have me some of that, so I drew up an adaptor flange for the airflow meter in Solid Works and sent it off to be laser cut in 3mm mild steel.

I then went and bought a 2.5inch mandrel bent horse shoe from my local exhaust shop and also had them make up a short 3inch flare for the filter. I cut off a 90 degree elbow from the horse shoe, squared off the end to match the flange, welded on the flare and made up some mounting straps. Then it was off to have it plated.

As nice as it looked all lovely and shiney, I was after discreet, so it copped a couple of coats of matte black.

Yes it's a Drift filter from Autobarn, but I kid you not, this thing came up trumps in back to back pod filter tests a couple of years ago. And for $36, who was I to argue!

As I mentioned in an earlier post, my cold air feed also came in for a bit of revision. I cut the top and bottom off the bellmouth so I could sit it further back in the bumper. A 90 degree pipe fitting was added to direct the airflow into some flexible tubing behind the bumper, and then exiting through a new opening in the lower panel within close proximity of the pod filter.

Then it was just a case of making a heat shield to take advantage of the cooler airflow, and it was done. Mind you, I did have to relocate the standard radiator header tank, which in itself was a pain the back side. But I think it was worth it.

So I ran it again at Winton and improved my previous best time by 1.5 seconds, so I was a very happy chappy.

So that's pretty much where it stands to date. Cheap and cheerful and whole lotta fun, even it is a front wheel drive. And most importantly, it owes me bugger all!