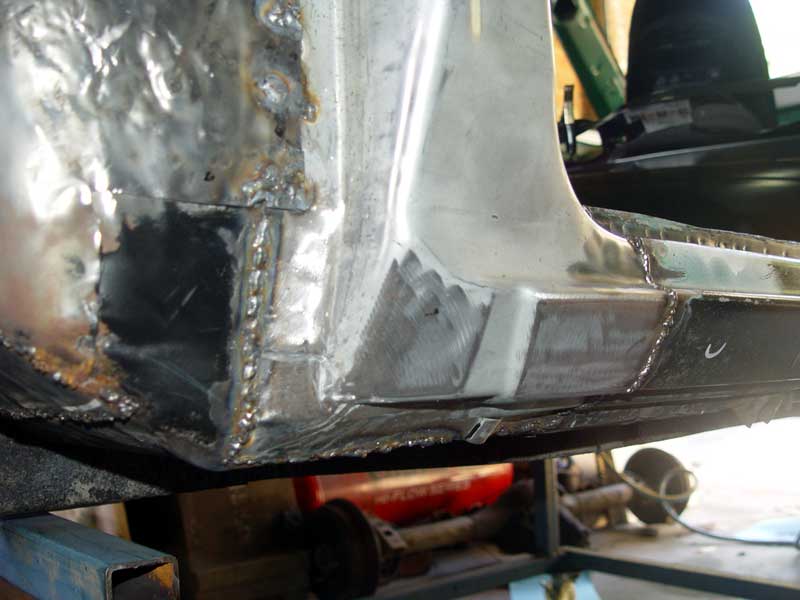

Welded the A pillar back on today... and ran out of MIG gas. Just have to grind a few welds flat (the visible ones).

First step was to weld the bottom part to the sill then the top to the original pillar. This was so both matched fairly closely as they'll be the visible part of the repair.

Next was the inner A pillar to the replacement along the door opening from top to bottom.

Then i drilled some new holes in the replacement A pillar along the front join and plug welded the new pillar to the inner pillar. Then i folded the forward outer panel back and plug welded through the holes left by the spot weld drill.

At this point I ran out of gas.

There's one patch left to do then the whole area gets a coat of etch primer then the seam sealer.

Also put in an order for a few more chassis gussets and strengthening bits. Should be here in a couple of weeks.

Next big job is the C pillar vents.