Got a little bit more done today, started on the firewall blanket and the roof insulation.

CAD helped a heap with both projects, progress on the firewall blanket is currently on hold while I wait for some joining strips to add the bits on the side of the tunnel in. I also need to cut some reliefs so it sits a little nicer on the floor pan, you can see where it bulges up on each side of the tunnel towards the footwell. Same on the very outer edge of the near the A pillars.

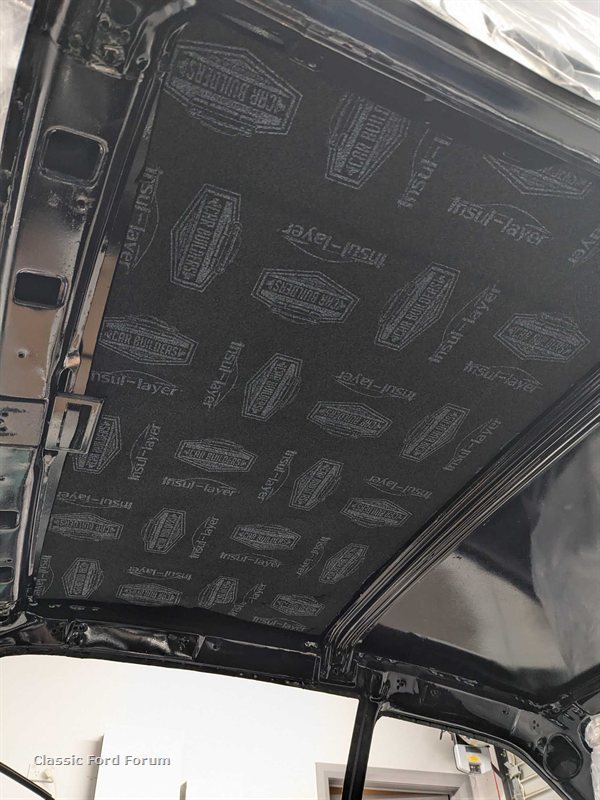

The roof was going swimmingly too - I used some tack glue and put two butyl mats up there (forgot to take a photo) then put the Insu-layer on, this is where I stuffed up a little, I had the pad off angle when I tacked it in above the drivers head - and there was no way it was coming back off without a tear. So I had to sacrifice that corner and start at the other side.

You can see where its a bit stuffed in that far corner, but i suppose the flip side is I know its never going to come off

.

Will tackle the back section tomorrow, least now I have a better strategy for tacking it down and it should go a lot smoother. Oh and the handbrake is all cleaned up and ready to go back in, that's tomorrows job too.

Also I got a quote from a mob in QLD that does alloy hubs for mk2 2L Aussie struts..... lets just say for what they were asking and the small benefit from the reduced rolling mass I am seriously considering sticking with standard hubs....

Attached Image(s)