Lost a few gaskets in the mix so slowed down final engine assembly for a bit

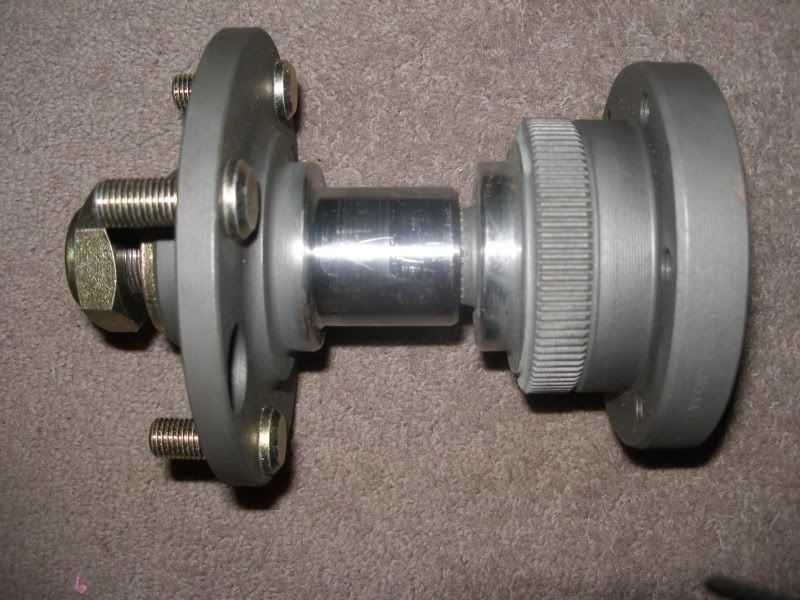

Thought I would show you and good plating solution I have found. I hope you all know you should not plate hubs, axles etc because of embrittlement possibly caused by the process (hydrogen and nitrogen trapped). Found a low temperature phosphate plating that is AOK.

Looks cool too like the grey cast iron. And pretty easy to mask certain areas (with race tape - 1002 uses!)

Also you can see the mods for the centrelock conversion - turned smaller id and od.